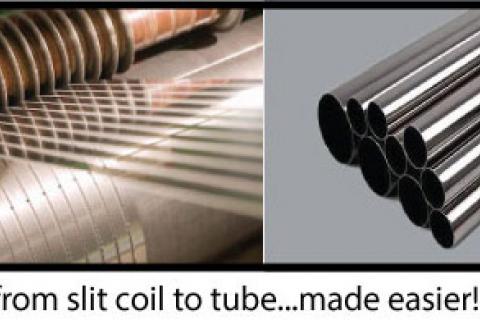

At United Performance Metals, our experienced team understands what tube mills require!

We know what makes a quality product, and we deliver. Slit coil for tubing applications must meet our customers' requirements for clean material with consistent shape and edge quality.

- Steel processing can be a dirty business. UPM takes extra steps in our slitting process to remove dirt or debris that can impede the welding process.

- Good tooling helps to minimize burr. Our shop maintains multiple sets of tooling for each slitter as well as a rigorous upkeep program.

- Reasonable run speeds help maintain consistency, but faster is not always better. The investments we've made in both our slitters and tooling allow the equipment to run with a high degree of precision with minimal tool marks on a strip.

- Don't forget the packaging! The right packaging helps keep the strip clean and safe and can save you time. We tailor our packaing to fit your specific needs.

United Performance Metals has 5 slitters capable of handling a variety of widths and thicknesses and comprehensive edging capabilities that can be customized to minimize camber for the tightest tolerance requirements. We have the metal you need, experience you can trust and the solutions you want!