Lightweight, strong, and corrosion resistant, titanium is a prized metal that plays a critical role in everything from aviation to medical implants. The journey of titanium starts deep within the Earth, not as a shining metal, but instead as a dull ore that must be extracted and processed to yield high-quality titanium that is free of impurities.

History of Titanium: Titanium was first discovered in 1791 by William Gregor, an English clergyman and amateur mineralogist, who identified a new metal in black magnetic sand from Cornwall, England. He named it manaccanite. In 1795, German chemist Martin Heinrich Klaproth independently discovered the same element in rutile ore and named it titanium, after the Titans of Greek mythology. Klaproth later confirmed Gregor’s earlier discovery, and the name “titanium” was adopted. However, isolating pure titanium proved difficult. It wasn’t until 1910 that Matthew A. Hunter produced 99.9% pure titanium using sodium reduction in a pressure cylinder. This was followed by the Kroll process in the 1930s–40s, developed by William Justin Kroll, which used magnesium to reduce titanium tetrachloride.

Mining and Ore Preparation: To begin the titanium process, this element must first be extracted from mineral deposits. Since titanium is not found in its pure form in nature, it is primarily gathered from ilmenite and rutile minerals. Ilmenite is a titanium-iron oxide (FeTiO3), which is the primary ore used for titanium due to its abundance in nature. Rutile is an oxide mineral composed of titanium dioxide (TiO2) that can also be used to form titanium. Once mined, the ore is crushed, washed, and processed using techniques like gravity and magnetic separation to concentrate the titanium oxide.

Kroll Process: The Kroll Process is the primary industrial method for producing titanium. This process occurs at temperatures around 1650-1830°F (900–1000°C) and combines titanium dioxide ore with chlorine to form titanium tetrachloride (TiCl4). Once the liquid tetrachloride forms, it is reduced by molten magnesium in a batch process. This reaction yields magnesium chloride and a porous, brittle material known as titanium sponge.

Sponge to Ingot: With the titanium sponge now formed, it is cleaned to remove any magnesium chloride using vacuum distillation or leaching. The titanium is then crushed into smaller granules, breaking it down from its sponge form. From here, large quantities of granules are compressed using extreme pressure to form compact blocks of titanium. These blocks are welded together and then melted in a furnace to create solid ingots.

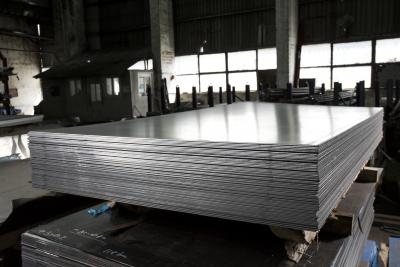

Forming the Final Product: Once the titanium is cast into ingots, it can be heated and forged to create various titanium products, including sheets, plates, and bars. The final product may also undergo additional processing, such as machining and polishing, to meet precise specifications and industry standards.

Titanium Applications: Titanium’s strength-to-weight ratio and corrosion resistance makes it ideal for aerospace use. By the mid-20th century, titanium was being used in rocket nozzle sleeves, satellite shells, spacecraft cabins, and military aircraft like the SR-71 Blackbird and A-10 Warthog. Additionally, titanium’s biocompatibility led to its use in medical implants, such as joint replacements and dental implants. Its corrosion resistance also makes it valuable in chemical processing, power generation, and marine applications.

UPM & Titanium Distribution: At United Performance Metals, we source high-quality titanium bar, sheet, coil, and plate directly from leading mills and make them available for customers across the globe. As a specialty metals solutions center, we ensure that customers have the right material, in the right form, at the right time. With extensive processing capabilities, a global inventory, and expertise in specialty metals, UPM helps you put titanium to work in your most demanding applications. To learn more about UPM’s titanium offerings, click here.

Posted October 01, 2025

Return to Blog