United Performance Metals provides nickel, titanium, stainless steel, and cobalt for aerospace applications, specifically aero engines. UPM holds several quality approvals, including AS9100D with ISO 9001:2015, AS13100, and DFARS, as well as a broad range of aerospace OEM approvals.

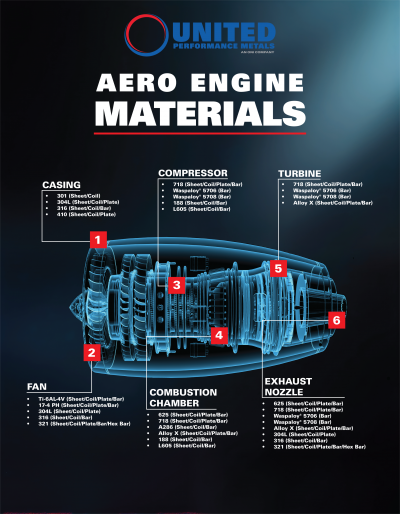

Casing: The aero engine casing houses the internal components of the engine and must be able to withstand high temperatures and stress. United Performance Metals carries four grades of stainless steel that are commonly used for aero engine casings. These grades include stainless 301, 304L, 316, and 410.

Fan: High power aero engine fans suck in tons of air that provide most of the engine’s thrust. Titanium and stainless steel are the most common materials used for this application due to their high strength-to-weight ratio and resistance to high temperatures. United Performance Metals carries Ti-6AL-4V, as well as stainless 17-4 PH, 304L, 316, and 321.

Compressor: The compressor pressurizes the air that was pulled in by the fan and squeezes it to make it smaller and increase its temperature. Nickel and cobalt are commonly used for aero engine compressor applications due to their high temperature strength and corrosion resistance during extreme conditions. United Performance Metals carries 718, Waspaloy® 5706, and Waspaloy® 5708 nickel products, as well as L605, 188, and Alloy 159® cobalt products.

Combustion Chamber: Inside the combustion chamber, fuel is mixed with high-pressure air, reaching temperatures up to 2100°C. Nickel materials 625, 718, A286, and Alloy X, as well as cobalt alloys 188 and L605, are used for these combustion chambers due to their stability at high temperatures.

Turbine: Inside the turbine, hot expanding gas pushes past a series of blades, resulting in power generation. United Performance Metals carries four grades of nickel material for turbine applications. These grades include 718, Waspaloy® 5706, Waspaloy® 5708, and Alloy X. Nickel is used for turbines due to its remarkable high-temperature strength and fatigue resistance.

Exhaust Nozzle: The exhaust nozzle produces thrust to help propel the aircraft forward. Nickel and stainless steel are the primary materials used for aero engine exhaust nozzles due to their high-temperature strength and superior corrosion resistance. United Performance Metals carries five grades of nickel material for exhaust nozzles, including 625, 718, Waspaloy® 5706, Waspaloy® 5708, and Alloy X, as well as stainless steel 304L, 316, and 321.

Posted June 19, 2025

Return to Blog